Numerical controlled (NC) machines have been used in their invention inside the Nineteen Forties and Fifties by John T. Parsons. The first laptop numerical managed (CNC) gadget changed into a born. At the same time, John Runyon used computer controls to produce punch tapes, sharply reducing the time required from 8 hours to an insignificant 15 minutes. In 1957, the United States Air Force and Massachusetts Institute of Technology (MIT) collaborated to produce the first NC machine managed entirely via PC.

Fast ahead more than 60 years later, and the concept of CNC machining has very few differences compared to its predecessor. Though CNC machining and manufacturing nevertheless produce 3-dimensional directions of output — X-axis, depth, and Y-axis — the scope of the method reaches far past what anyone ought ever to imagine. 2018 is positive to convey new strides on this flexible technique, including the following traits:

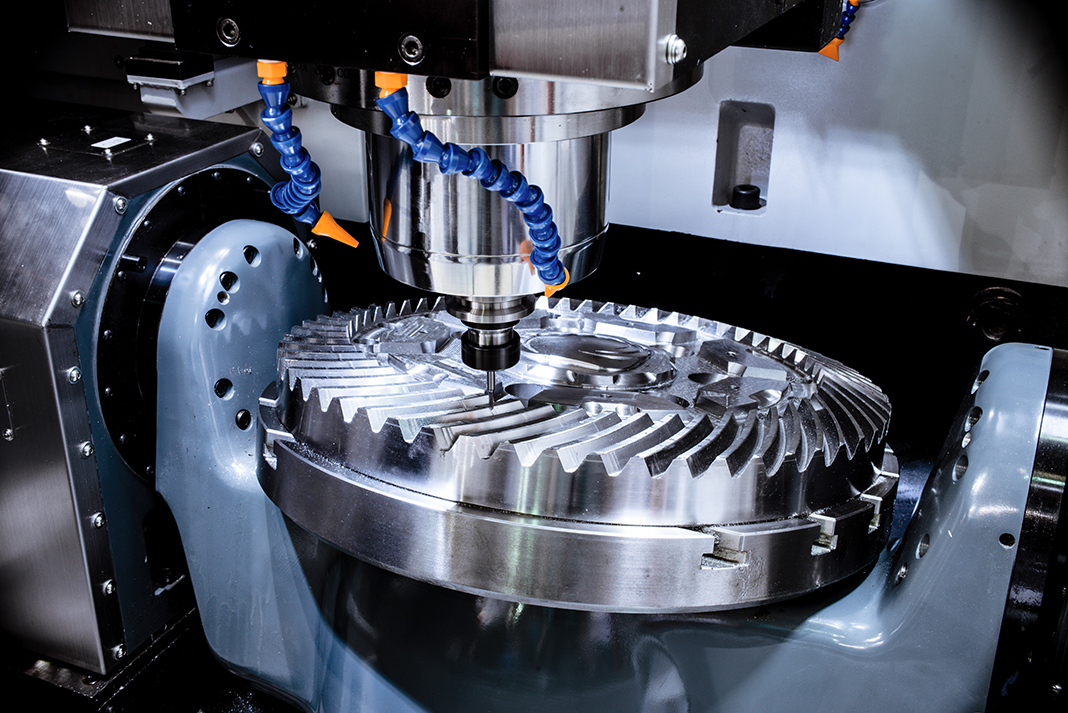

1. Complex Cuts Made Even Easier

Refinements in CNC machining will retain to make complicated cuts — including incline floor holes, contours, and more fabulous — even more accurate and smooth. The assignment’s parameters can be defined in several unique planes to generate the consequences that a customer expects within the time frame wished.

2. Touchscreen Technology

Today, touchscreen technology is expected in smartphones and is increasingly becoming the norm for laptops and computers. These are not the most straightforward merchandise taking benefit of this era, although. Touchscreens are included with CNC machines to deliver specific programming. This is handy, short, and intuitive. Built-in capabilities are constantly updated and designed to shave valuable time from programming parameters. These permit operators to deftly navigate through a range of content, complicated tables, long lists, and expansive applications to find the required factors to finish tasks.

3. Embrace New Materials, Tools, and Processes

A dizzying array of recent and progressive materials has evolved each yr, supplying groups with new possibilities to deliver merchandise that meet their target audiences’ needs. CNC machining provides processes and gear that meet the demanding situations of bringing those new substances to market. With the right features on the ready, CNC manufacturing tackles innovative projects with precision and speed.

4. The Trickle-Down Effect

Some industries, including the aerospace and vehicle sectors, require strict tolerances, fantastic floor high-quality, and the ability to endure dynamic loads. These similar techniques can also be implemented in the manufacturing of smaller-scale objects as well. The result is artistry and satisfaction. This is unsurpassed.